Category: All

And this leads to why EB Industries had such an astonishingly low weld failure rate. The visiting engineering team determined the difference between EB Industries and other laser welding vendors came down to adherence to best practices and standards, differences in operator training, use of automation, and quality control procedures. In short, our zero percent weld failure rate is a by-product of our long standing engineering culture.

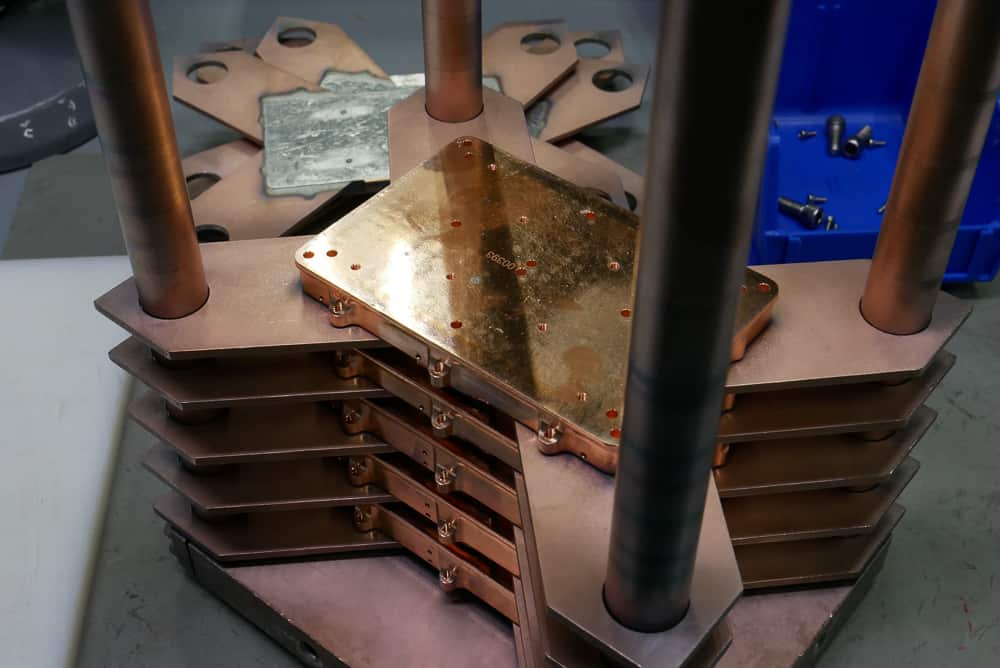

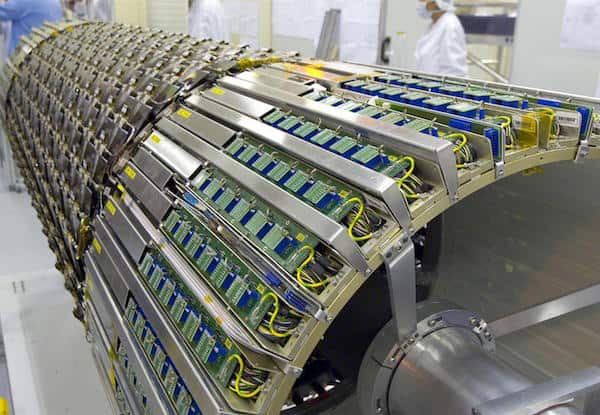

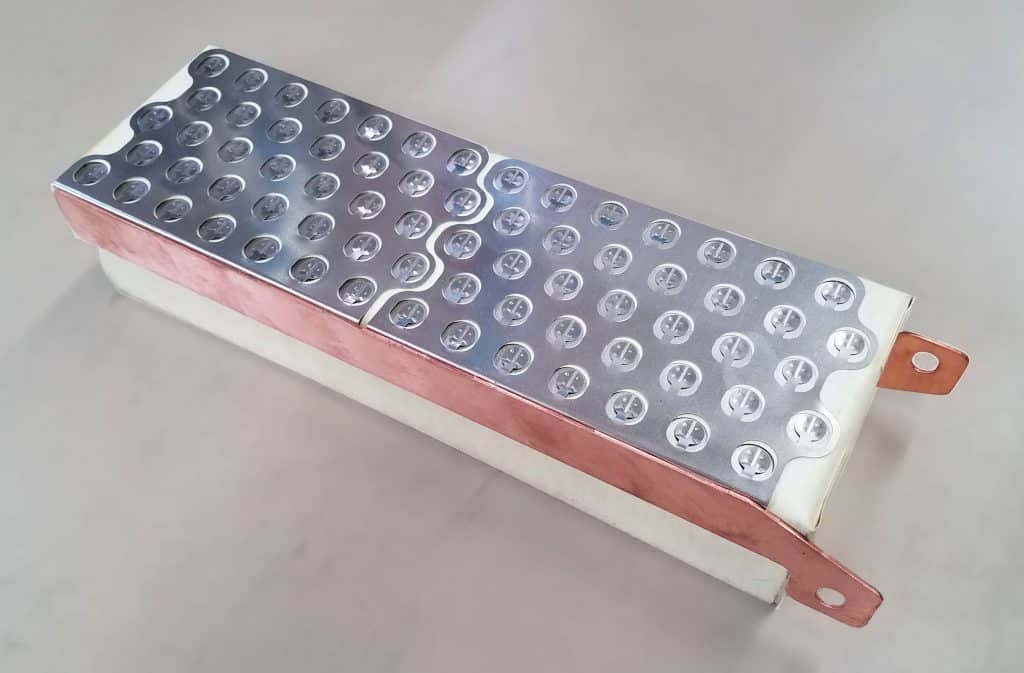

EB Industries was founded in 1965 and started out doing precision electron beam welding for the aerospace industry. Our early work was on commercial and military aircraft parts, on satellites, and on the Apollo moon project, and all of that work was to exacting mil-spec and proprietary standards. Our entire system of doing business was essentially set-up around meeting high standards, and as we evolved and expanded into other end user industries, such as medical and energy, and added technologies, such as laser welding and hermetic sealing, we brought along a rigorous in-house training system, an equipment maintenance program, and a quality management system that is beyond industry standard.Early on, EB Industries adopted computer control of virtually all facets of electron beam welding, and that philosophy has been extended to our laser welding and hermetic laser sealing services. We never hand weld anything when we can instead create proper fixturing and automate the welding process such that it is reliable and repeatable. We use glove boxes whenever possible to increase weld purity, such as when welding titanium. We have the test equipment available and the knowledge of its use to thoroughly check and test what we assemble and weld. We have a highly experienced engineering staff to consult with customers and design joint configurations that take into account everything, from metallurgy to environmental conditions, and all of this is basically done to the same standards used for spacecraft, aircraft, or critical military equipment.

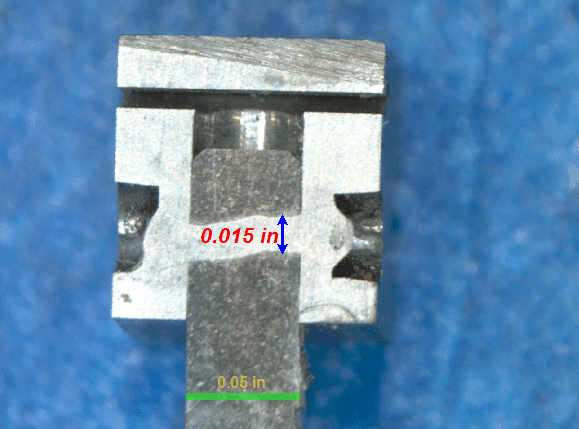

Our quality processes, and our plant culture in general, are also unique in that we rely on positive verification that our welds are applied as required for every job, every lot, and when required, every part. We have an onsite materials lab that specializes in cutting and potting welded parts to analyze depth of penetration, width of weld bead, porosity, and a number of other factors that verify a quality weld. When a customer can’t spare a production part to sacrifice, we create separate test pieces of similar material and configuration to confirm our operators and equipment are performing as required. We also employ a number of non-destructive test methods, such as liquid penetrant, x-ray, and CT scan, when weld quality must be assured for every part.

We’ve always known that EB Industries is different from most of our competitors, and we’ve always been confident in the efficacy of the quality driven engineering culture at EB Industries. At the end of the problem solving round table with the ten engineers, it was affirming to have proof that what is central to our business truly makes a difference to our customers.

[ServiceCTA]